The ERP Reality Check: Why Australian Mid-Market Companies Need Integrated Ecosystems to Thrive

After two decades implementing and integrating enterprise systems across Australia's manufacturing and distribution sectors, at ThynkProcess, we've witnessed a fundamental shift in how successful companies approach their technology strategy. The days when a standalone ERP system could drive competitive advantage are well and truly behind us.

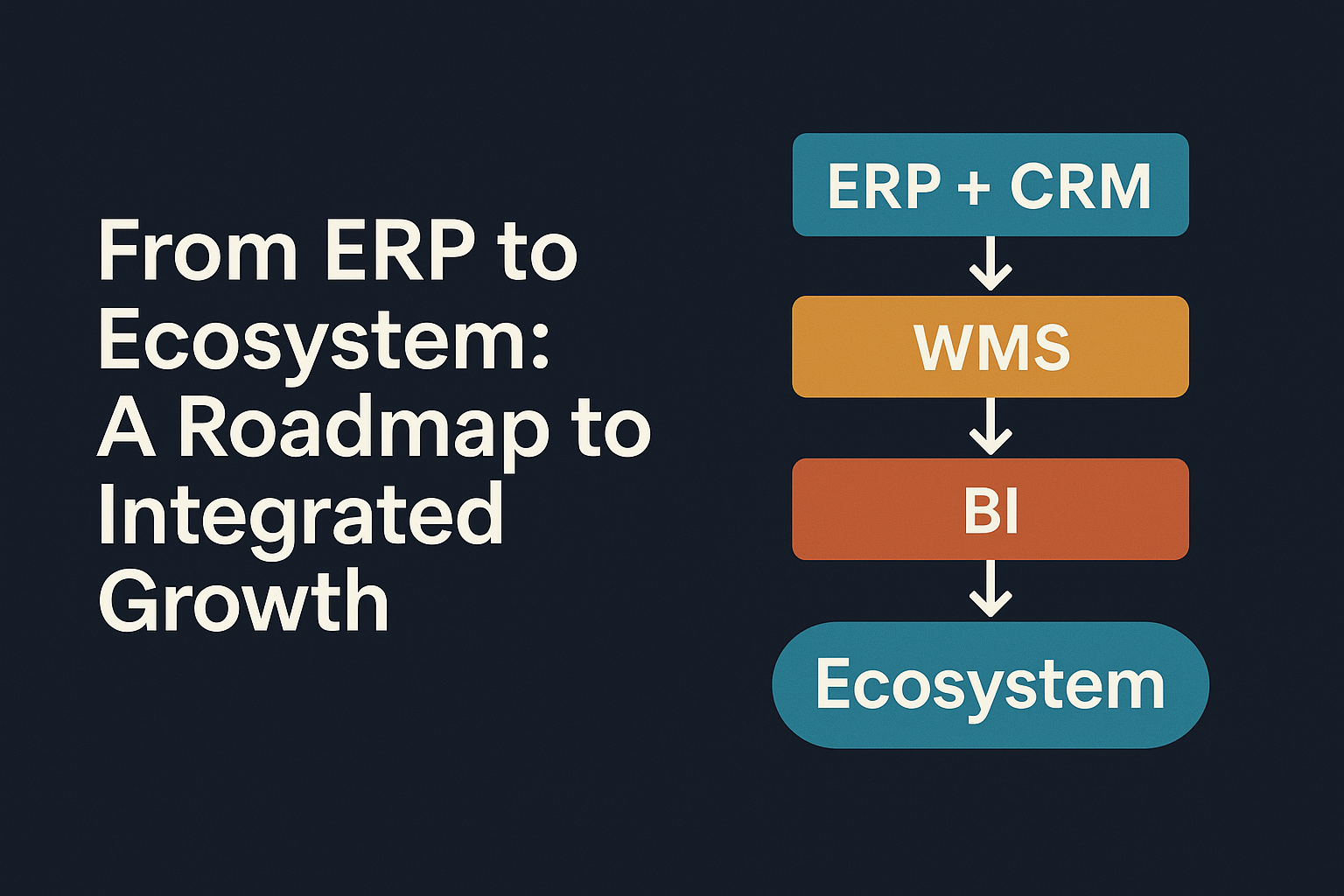

Yes, ERP is the backbone — it handles finance, inventory, and operations. But in today’s volatile supply chains, increasingly demanding customers, and razor-thin margins, ERP needs to connect with the wider ecosystem. The companies that thrive aren’t the ones with the biggest ERP deployment — they’re the ones who integrate ERP with CRM, WMS, and BI into a seamless flow of data, insights, and actions. Integration has quietly become the real growth driver. In today's hyper-connected Australian market—where supply chains stretch from Perth to Brisbane and customer expectations are shaped by global e-commerce giants—mid-market companies are discovering a sobering truth: ERP alone is like having a powerful engine without the transmission, wheels, or steering system.

The companies winning in Australia's competitive landscape aren't just running better ERP systems; they're orchestrating integrated technology ecosystems where ERP, CRM, WMS, and BI tools work in perfect harmony. Here's why this integrated approach has become the definitive growth differentiator.

1. Real-Time Visibility Across the Entire Value Chain

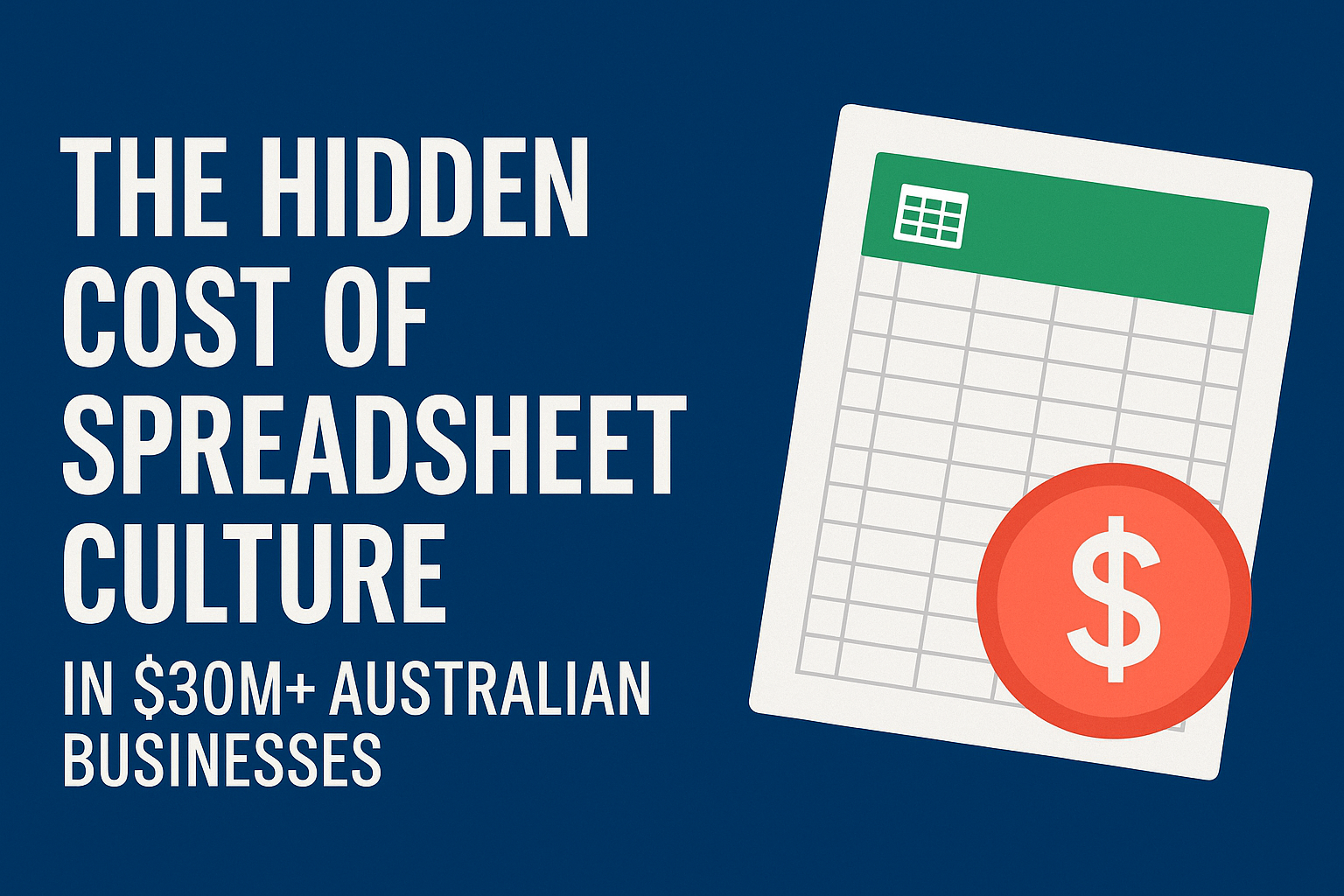

Traditional ERP implementations in Australian manufacturing and distribution typically focus on core financials and basic inventory management. But consider this scenario: your Melbourne warehouse receives an urgent order from a key customer in Sydney, while your sales team in Brisbane is promising delivery dates based on outdated inventory data, and your finance team is working with yesterday's numbers to make critical pricing decisions.

This fragmented visibility is costing Australian companies millions annually. When ERP integrates seamlessly with warehouse management systems (WMS), customer relationship management (CRM), and business intelligence (BI) platforms, something transformative happens—you gain what I call "operational prescience."

Integrated systems provide CXOs with real-time insights that span from raw material procurement to customer satisfaction scores. Your sales team sees live inventory levels from multiple warehouses, your procurement team receives automated alerts when customer demand patterns shift, and your executive dashboard consolidates everything from cash flow to customer lifetime value in real-time.

One of our recent implementations for a Melbourne based industrial distributor resulted in a 34% reduction in stock-outs and a 28% improvement in order fulfilment accuracy within six months—not because their ERP got better, but because their integrated ecosystem eliminated information silos that were creating costly blind spots.

2. Automated Workflow Intelligence That Scales Operations

Australia's skilled labor shortage isn't going away. The Australian Bureau of Statistics reports continued challenges in finding qualified warehouse, manufacturing, and administrative staff. The companies that are growing despite these constraints have one thing in common: they've automated the routine so their people can focus on the strategic.

True integration creates intelligent workflows that span multiple systems without human intervention. When a customer places an order through your e-commerce platform, integrated systems can automatically check inventory across multiple locations, optimise picking routes in the warehouse, update delivery schedules in real-time, trigger automated communications to the customer, and adjust demand forecasting models—all without a single manual handoff.

This level of automation is impossible with standalone ERP systems because they can't see beyond their own functional boundaries. But when ERP talks directly to your CRM, WMS, and BI tools, you create what I call "intelligent operations"—systems that don't just process transactions but actually learn and optimise continuously.

Another Victorian manufacturer we worked with eliminated 67% of manual data entry tasks and reduced their order-to-invoice cycle time from 8 days to 2.5 days through seamless integration. Their team now focuses on customer relationships and strategic initiatives rather than chasing down order status updates and reconciling disparate systems.

3. Predictive Intelligence for Proactive Decision-Making

Here's where integrated ecosystems truly separate the leaders from the followers: predictive capabilities that turn historical data into forward-looking intelligence. Standalone ERP systems are inherently reactive—they tell you what happened after it's already occurred.

Integrated systems transform your data into competitive intelligence. When your BI platform can analyse customer behaviuor patterns from your CRM, cross-reference them with inventory movements from your WMS, and combine this with financial trends from your ERP, you unlock predictive insights that drive proactive decisions.

Consider demand forecasting in Australia's seasonal markets. Traditional ERP-based forecasting might predict a 15% increase in demand based on historical sales data. But an integrated system can factor in customer engagement scores from your CRM (indicating growing account potential), real-time market intelligence from your BI platform (showing competitor pricing trends), and warehouse velocity data from your WMS (revealing which products are actually moving faster despite lower sales volumes).

This multi-dimensional intelligence enables Australian companies to anticipate market shifts, optimise inventory investments, and capture opportunities that competitors miss because they're working with incomplete information.

The Integration Imperative

Australian mid-market companies face a critical decision point. The businesses thriving in today's environment aren't necessarily those with the biggest technology budgets—they're the ones that have recognised integration as a strategic necessity, not a technical nice-to-have.

The question isn't whether to integrate your enterprise systems; it's how quickly you can achieve seamless integration that drives real business outcomes.

Ready to transform your technology ecosystem into a competitive advantage? As Australia's fastest-growing SAP Business One Partner, ThynkProcess specialises in creating integrated solutions that drive measurable growth for manufacturing and distribution companies.

Let's explore how integrated ERP, CRM, WMS, and BI can accelerate your business objectives. Message us directly or email info@thynkprocess.com.au to arrange a 30 min Discovery Session to uncover why leading Australian mid-market companies choose ThynkProcess for their integration journey.

Simply email us at info@thynkprocess.com.au or call (03) 7075 3900 and one of our certified consultants will contact you within 48 hours.

.jpeg)